KWPA Donates Pennsylvania Hardwood Educational Display to the Williamsport Regional Airport

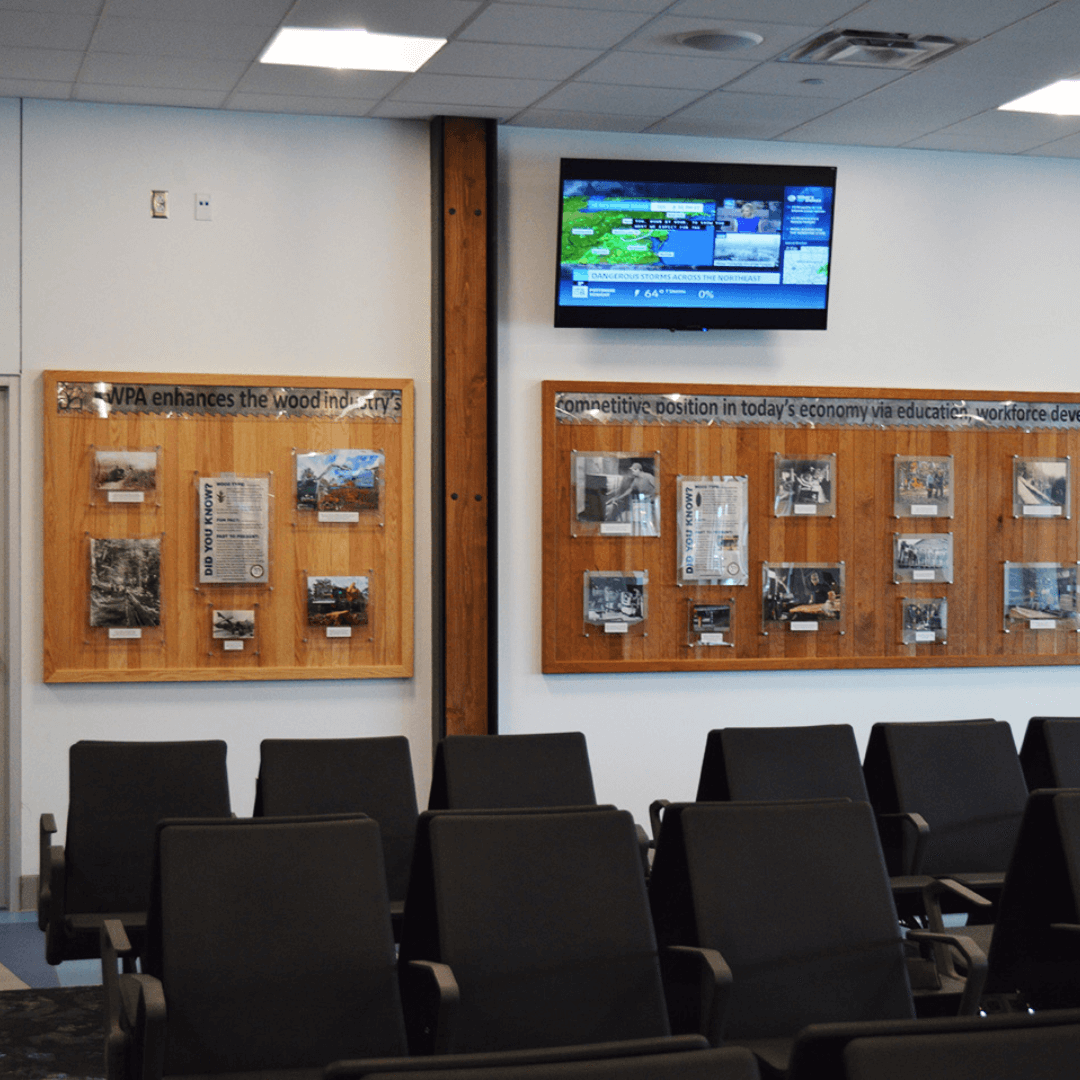

The new terminal at the Williamsport Regional Airport showcases the area’s rich lumber heritage thanks to an educational initiative spearheaded by Keystone Wood Products Association (KWPA)—a non-profit organization dedicated to securing the future of the wood products industry. As part of its organizational outreach efforts, KWPA and its members donated a display comprised of an interactive wall and six hardwood panels to the state-of-the-art facility.

“It’s an honor to share the industry with airport visitors,” says past KWPA chairman of the board, Scott Seyler.

The idea gained momentum over two years ago when the KWPA board learned that the Williamsport Regional Airport was constructing a new terminal.

“We contacted Tom Hart--the director of the airport. Thankfully, he shared our vision and put us in touch with the airport architects. The rest is history,” says Seyler.

The educational endeavor unfolded in two phases. Phase one—an interactive wall— allows passengers awaiting their flights to learn a myriad of industry information by interacting with a touch screen monitor which is encased in a beautifully handcrafted walnut frame.

“For the interactive wall decor, we enlisted the help of KWPA member, James Vanderlin Company. Their team did an outstanding job of designing and framing the wall components,” says Stephanie Phillips-Taggart, KWPA marketing coordinator.

The case sits below an impressive photograph of the Susquehanna River wood hick statue taken by local photographer Eric Stashak.

“The wall is impressive,” says Nicholas Bisaccia, KWPA Chairman of the board. “Not only is it visually appealing, but by using the touch screen, you can learn about sustainable forestry, wood products, and KWPA members. The monitor, which was programmed by staff at the Pennsylvania College of Technology, exhibits a broad depth of industry information.”

Phase two of the project consists of six Pennsylvania hardwood panels constructed of Ash, Red Maple, Red Oak, Birch, Hickory, and Cherry.

“Adorned with photographs and information, the panels were a team effort,” says Phillips-Taggart. “The hardwood was donated by the Pennsylvania College of Technology and profiled by Lewis Lumber Products. Students and instructors at SUN Area Technical Institute manufactured the panels. The project was completed by Jim Vanderlin and Company, who assisted with placing the imagery and information on the panels.”

Each panel hosts historic and modern-day industry images, forest facts and tree species information displayed by modern standoff systems. An actual band saw blades, donated by GM Bandsaw, Montgomery, adorn the top of the panels and share KWPA’s mission of securing the future of the industry via workforce development, education, and promotion. The lettering was provided by Croft CNC of Williamsport.

Historic images were obtained from several sources—including the Bill Brooks family collection, the Lycoming County Historical Society and the Union County Historical Society. Modern-day imagery was provided by entities such as the PA Hardwood Development Council, Pennsylvania College of Technology, Dwight Lewis Lumber, Lewis Lumber Products, the James Wood Company, and Eric Stashak.

Visual collections focus on the Susquehanna River/boom; sustainable forestry/harvesting; sawmills; lumber life in the 1800’s; transportation and workforce. Each panel captures images from the 1800s to the present day.

“One of my favorites is the historical photo of a log slide. It was innovative back in the 1800s,” says Phillips-Taggart. “Today, skid steers and log trucks have replaced gravity and horse/mule power. It’s a vivid reminder of how far the industry has come.”

Posters also adorn the panels and share facts that may be surprising to the general public.

“Many people do not understand that responsibly harvesting timber has maintained growth,” says Bisaccia. “There is more timber today in the Commonwealth than there was 100 years ago.”

Other facts include:

The wood used in long-term projects such as furniture, cabinetry, flooring, and construction store carbon in solid form for hundreds of years, which reduces air pollution.

By-products from tree harvesting and lumber production are used for mulch, wood pellets, animal bedding, paper pulp, fuel, and biomass energy—leaving no waste behind.

Trees are a renewable resource. Unlike other raw materials, trees regenerate naturally.

Phase two alone used approximately 200 standoffs, 8 posters, 40 photos, and took over 30 hours to install.

“Our passengers enjoy learning more about the area’s rich heritage,” says Tom Hart, executive director of the airport. “To me, it’s about our roots—the lumber heritage.”

The airport hosts 45-60,000 visitors annually.

“It is our hope that each of those visitors learns something about the industry. We are appreciative of this opportunity,” says Seyler. “Through outreach efforts such as this, we are dedicated to preserving the past, embracing the present and securing the future of the wood products industry.”

Keystone Wood Products Association (KWPA) strives to strengthen and expand the base of lumber and wood product manufacturers in the Central Pennsylvania region. KWPA’s ultimate mission is to maintain and enhance the industry’s competitive position in today’s global economy. KWPA outreach efforts include partnering with local school districts to offer educational presentations, providing workforce development opportunities and participating in special events to promote the wood products industry. For more information, visit www.whypahardwoods.com.